產品

Peptide synthesizers 5 – 500 liter

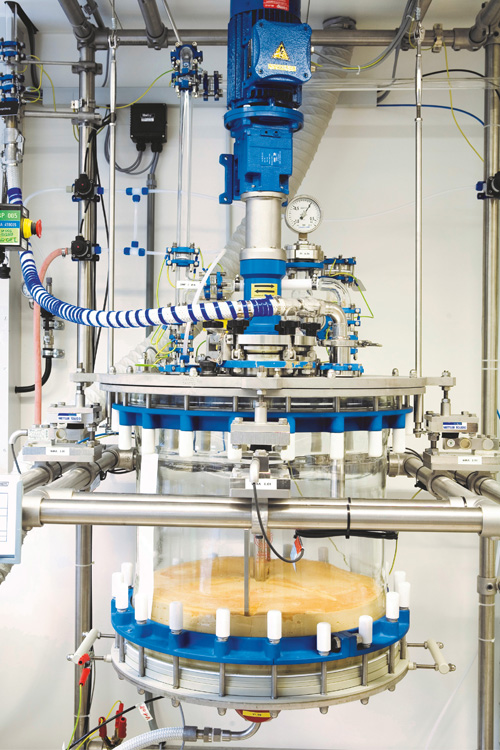

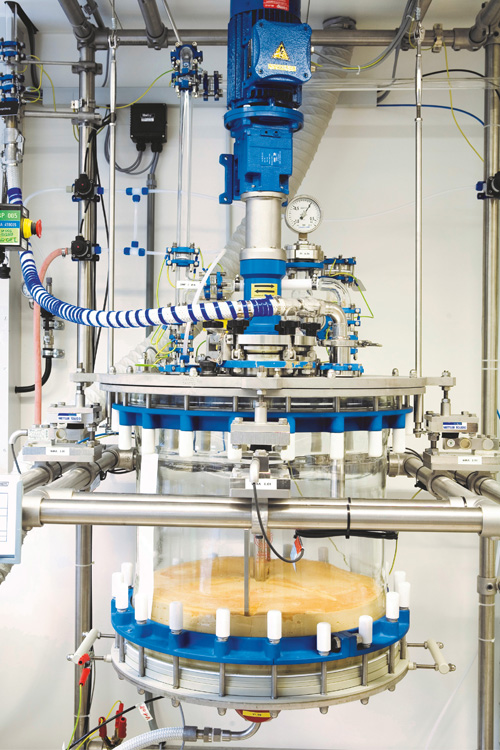

Buchiglas peptide synthesizer reactor solutions

| Filtration vessel: | 5 to 500 liter |

| Pressure: | -1.0 (FV) to +0.5 bar |

| Temperature: | -60 °C to +150 °C (200 °C) |

| Filtration vessel: | 5 to 500 liter |

| Pressure: | -1.0 (FV) to +0.5 bar |

| Temperature: | -60 °C to +150 °C (200 °C) |

Solid phase peptide synthesis (SPPS) is an established method for peptide synthesis. It is a process in which a peptide anchored to an insoluble polymer (resin) is assembled by the successive addition of protected amino acids forming its sequence. It is a widely utilized for synthesizing peptides efficiently and reliably – from lab to commercial scale.

At Buchiglas, we understand the critical role that reactor technology plays in achieving successful synthesis results. With decades of experience and a market leading position in peptide synthesis, we provide tailored solutions to run both manual and fully automated processes.

Our systems range from standardized to customized solutions and are available in scales from lab trough pilot/kilo lab up to commercial production volumes (5 – 500 liters). All ensuring exceptional consistency and reproducibility of synthesis results. All systems are cGMP compliant and are suitable for the production of high-quality peptide active pharmaceutical ingredients (APIs).

Our peptide synthesizers for manual synthesis are specifically engineered for ease of operation and to provide optimal synthesis conditions. Each system typically consists of a lowerable cylindrical glass vessel equipped with a dry-running mechanical ATEX stirrer and a swing out filter plate.

This design enables thorough mixing and efficient filtration, critical for effective deprotecting, coupling, washing and cleavage steps throughout the synthesis route.

Key features include:

Find out more about our standardized portfolio of peptide synthesizers (from 10l to 50l).

For operators seeking enhanced efficiency, scalability, and batch to batch consistency, Buchiglas offers fully automated reactor systems tailored for SPPS. Designed to support batchwise synthesis based solvent and reactant dosing on either volume or weight, these systems ensure precise, reproducible, and operator independent workflows across all stages of peptide production.

Automation features include:

With Buchiglas peptide synthesizers, whether manually operated or fully automated, researchers, kilo lab operators and production chemists can confidently achieve high quality, reproducible peptide synthesis, tailored precisely to your unique processes and production needs.

Since decades, globally leading peptide manufacturers use Buchiglas peptide synthesizers in various scales for the successful development and cGMP production of highest quality peptide products.

For customized peptide synthesizer solutions, please get in touch with us directly or via our local distributor.

Fully automated peptide synthesizers

Manually operated peptide synthesizers