Products

Glass reactors & process equipment

Pressure reactors / stirred autoclaves

Other products

Buchi uses state-of-the-art engineering methods, procedures and software to develop, and design reactor systems and process equipment that fulfill the most demanding customer requirements while guaranteeing the highest level of safety and reliability.

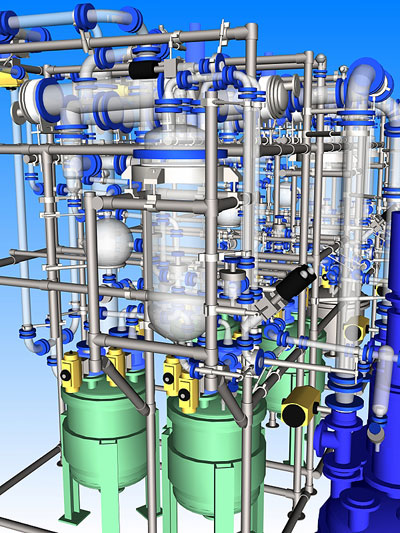

Buchi uses state-of-the-art 3-D engineering software for the design and engineering of all its reactors and process equipment.

Using such engineering software enables the customer to verify the setup of the equipment and its functionalities as well as the integration into the existing infrastructure (incl. all required connections).

Please find below a link to a free download of a viewer software.

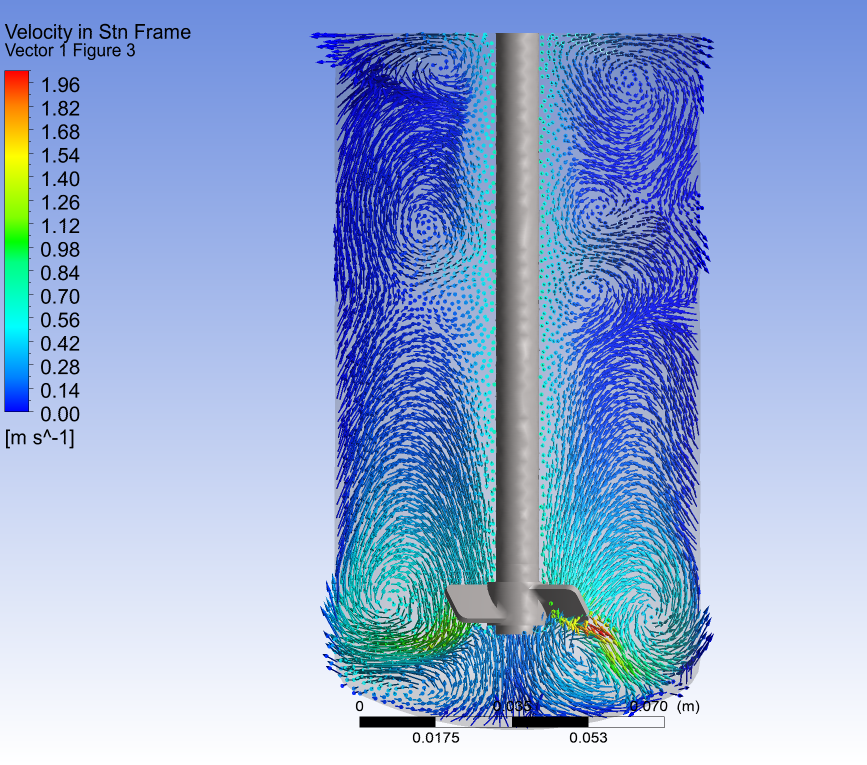

We use CFD simulation to analyze and evaluate the mixing behavior of various media (high to low viscosity) and media systems (single phase, multiphase including liquid, gas and solids) in our reactor systems.

Using CFD simulation we are able to select and optimize the appropriate geometry of stirrers, baffles and reactor vessels, determine critical rotational speeds of the stirrers and the required torque as well as model the heat transfer.

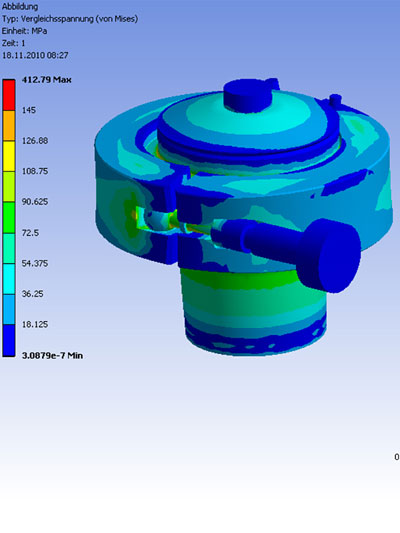

Buchi has long-standing experience and a high level of expertise in the application of finite element method (FEM) simulation in engineering. Whenever structural analysis is required to determine critical structural parameters of reactors and process equipment (such as selection of materials, wall thickness, vessel geometry etc.), FEM simulation is used.

The use of this advanced simulation method guarantees highest operational safety and reliability of the apparatus.