Products

Glass reactors & process equipment

Pressure reactors / stirred autoclaves

Other products

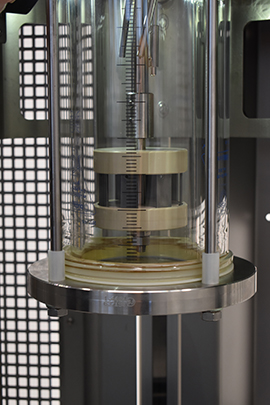

Corrosion testing requires the realistic simulation of process environments that often involve high pressure and high temperature (HPHT) conditions. The corrosion testing systems are designed to reproduce these environments accurately and reliably.

Thanks to our proprietary designs and the use of high-performance materials, our industry-leading high-pressure and high-temperature (HPHT) corrosion testing autoclaves and pressure reactors are suitable for the most challenging corrosion testing applications.

Due to our proprietary designs and the use of high-performance materials, HPHT corrosion testing pressure ractors deliver exceptional durability and precision, even under the most demanding test conditions. They are ideal for corrosion inhibitor testing, materials evaluation, and long-term corrosion monitoring.

In addition to the weight loss testing, these pressure reactor systems support electrochemical corrosion measurement methods such as Linear Polarization Resistance (LPR) testing. This allows for real time corrosion rate monitoring and offers valuable insights into corrosion behavior and inhibitor performance under simulated conditions.

We collaborate closely with clients from a wide range of industries, including oil and gas (upstream and downstream), petrochemicals, steel, nuclear and conventional power generation, and inspection, certification, and testing organizations, to design, engineer, and manufacture customized corrosion testing solutions for their specific applications.

Specification possible until:

| Reactor volume: | 0.1 liter - 5.0 liter |

| Pressure range: | 1000 bar |

We have longstanding expertise in the design, engineering and manufacturing of corrosion testing autoclaves made from different corrosion resistant materials such as: